-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

Need an overhead crane: Where to start?

10:35

By Alexandre Venne

Are you planning to buy lifting equipment? But above all, you certainly want to make the right choice to avoid any regrets! So where do you start to achieve this goal? What are the first steps to making your project a success?

Over the past 15 years, Premium Industrial Group has helped hundreds of companies choose and install custom-built overhead cranes. We install between 200 and 250 cranes of various types every year.

By the end of this article, you'll know what the first steps are in an overhead crane purchase project, whether for a new location or an addition to an existing crane runway. You'll also learn what information you need to gather to configure the right lifting equipment for your needs.

Here's what you'll discover :

The first 3 stages of an overhead crane project :

1. Determine the considered lifting application

2. Gather information relevant to the project

3. Contact a lifting specialist

Step 1 : Determine your overhead crane application: the key to making the right choice!

In lifting, the application means the use to which the equipment will be put. In other words, what are you going to lift with your crane, how, how often and in what environment? This information is the key to determining the right equipment.

In lifting, the application means the use to which the equipment will be put. In other words, what are you going to lift with your crane, how, how often and in what environment? This information is the key to determining the right equipment.

To help you make the right choice, here are the elements that make up the application.

What : the parts

• What parts are you going to lift?

• How are they made? What are their dimensions?

• What are their maximal weight?

• Any other relevant information about the parts

How : the operations

• What operations do you need to perform?

• How will the part be attached or secured to the crane for maneuvering? With slings, spreader bars, suction cups, magnets, etc.?

• Describe the handling you need to do with the part (movement, rotation, etc.)

• Describe the path the part will take from point A to point Z?

When : the frequency

• How often will you move your parts (number of lifts / hour)?

Where : the environment

• Will the equipment be installed indoors or outdoors?

• Is it a hazardous environment, containing frammable gases or unstable particles in the air?

• Is it a corrosive environment? Is the temperature high (over 40 degrees, for example)?

Clearly defining the application will help you gather the other information you need to assess your requirements and possible configurations.

What if I just want to add an overhead crane to an existing crane runway? Even then, all this information will be relevant, as it forms the basis of an overhead crane project. In fact, in the case of an addition, more information will be required. It will be discussed later in this article. |

Step 2 : Gather the information you need for your overhead crane project

The application is the most important element that will give your project a clear direction. But then, what other details will your supplier need to know in order to prepare a quotation?

Here's a list suitable for most lifting projects.

The amount

• overhead cranes• monorails

• jib cranes

• etc.

The capacity

Often determined by the heaviest weight to be lifted. This will determine the rated capacity of your equipment. The rated capacity represents the maximum weight the crane can lift according to its design.

Tip: It is generally advisable to allow for an additional margin when evaluating the required rated capacity. For example, if the load handled is frequently close to the equipment’s maximum limit, it is recommended to select an overhead crane with a capacity approximately 10% higher.

The deadline

When do you need the cranes to be operational? There are several stages in an overhead crane project, including design, manufacturing, delivery, installation and commissioning (For more information on the stages of a project, see the article The 5 steps of a crane project and your role in its success!). This will enable you to see if the target date is realistic, compared with the time needed to complete the various stages.

The location

• Is it a new building?

• Where is it located?

• In which section of the building will the equipment be installed?

The dimensions

Several dimensions need to be measured to configure your overhead cranes to your environment :

The lifting height

Necessary height between the ground and the top of the part in its highest position.

The clear height

Over the entire surface area where the crane will travel: Available height between the ground and the lowest obstacle.

Length and width of available space

Length and width dimensions of the installation site. These dimensions will be used to determine the length of the crane runways and the overhead crane span.

General arrangement drawing

Your lifting specialist will need to visualize the layout you're planning. If no plan has yet been drawn up, for example, if you're at the very beginning of the project, you can provide a drawing of the layout you have in mind.

The obstacles

It's also very important to identify on the plan the location of obstacles that could create an obstruction to the overhead crane’s movement. The most common are :

• Garage door tracks

• Lights

• Etc.

For more information on obstacles that can hinder your project, see Managing clearance and avoiding obstructions leads to unhindered installations

The structure

This is the base, usually made of steel, supporting the rails on which the overhead crane travels. In a new building, this structure is often already provided by the contractor. But if not, you should mention it to your specialist. There are several options for self-supporting or semi- self-supporting structures (see the Overhead crane structure page).

supporting the rails on which the overhead crane travels. In a new building, this structure is often already provided by the contractor. But if not, you should mention it to your specialist. There are several options for self-supporting or semi- self-supporting structures (see the Overhead crane structure page).

When a structure is to be added to the quotation, the following information is required :

The thickness of the floor

Concrete floors are often 6" thick in industrial environments. But if the floor is thinner, certain solutions may be required.

See the article How thick should my concrete slab be to install an overhead crane structure?

The presence of radiant floor heating

It's important to know the location of underfloor heating systems, for example for drilling.

The position of the columns

Incorrectly positioned columns can interfere with your operations.

Electrical voltage

The nominal voltage required for an overhead crane installation is 600V three-phase (600Vac/3ph/60Hz). If this type of power supply is not available, you should mention it to your specialist to determine your options.

Information required when adding an overhead crane to an existing crane runway

If your project involves adding one or more cranes to an existing crane runway, most of the information described above will be required. But your lifting specialist will also need the following additional information :

Layout plan including current overhead cranes

In the case of an existing runway, the layout plan provided should include the current installations, in order to visualize the project as a whole.

Capacity engineering

There's a limit to the capacity your current crane runway can support. When adding an overhead crane, the engineering of your structure will establish the safe distance that must be kept between the equipment to respect the maximum capacity. If you don't have the engineering documents on hand, you'll need to consult an engineer.

To find out more, read our article Capacity restriction on a runway track: 7 solutions!

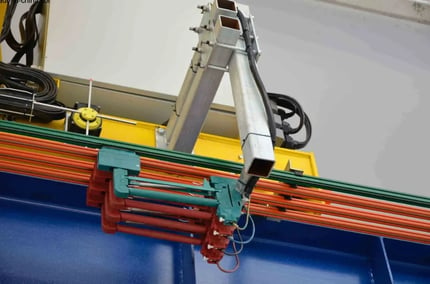

The conductor bars

The power supply has also been designed with limits based on the current layout. Your supplier will therefore also need to know the brand and model of the current conductor bars to check whether any modifications will be necessary.

To find out more, read our article Adding an overhead crane: the 3 essential checks .

Information on current overhead cranes

Particularly when the crane to be added will serve the same purpose as those already in place, we'll try to match its specifications as closely as possible. The following information will be useful :

• The brand of the existing cranes and hoists

• The speeds of the equipment

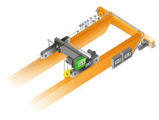

• Whether the cranes are single or double girder

• Whether the cranes are top running or under running

• Any other relevant information on current equipment

Single girder

Double girder

Under running

Top running single girder

Top running double girder

Application and information : Checklist and summary table

To make your work easier, we suggest you download our checklist here. It's a handy way of gathering information in one place.

Below, you'll also find a table summarizing all the application elements and necessary information, so you don't forget anything.

Summary table of application and general information

Application |

||

What |

The parts |

· Maximal weight |

How |

The operations |

· How will they be secured and moved? |

When |

How often |

· Number of lifts / hour |

Where |

The environment |

· Indoors |

General information |

||

Amount |

Number of equipment of each type |

|

Deadline |

When do your cranes need to be operational? |

|

Location |

Where it will be installed |

|

Plan |

Drawing of desired layout |

|

Obstacles |

Heating units |

|

|

Garage door rails |

||

|

Lights |

||

Dimensions |

Lifting height |

|

|

Clear height |

||

|

Length of available space |

||

|

Width of available space |

||

Plan |

Drawing of desired layout |

|

Structure |

If your supplier needs to provide it… |

|

Electrical voltage |

600Vac/3ph/60Hz |

|

Additional information for adding overhead cranes to an existing crane runway |

||

Capacity engineering |

What are the capacity restrictions of the runway tracks? |

|

Conductor bars |

Brand and model of current conductor bars |

|

Current overhead cranes |

Brand |

|

|

Speeds |

||

|

Single or double girder |

||

|

Top running or under running |

||

|

Other relevant information |

||

Step 3 : Contact a crane specialist to find the best solution

Once all this information is gathered, you're ready for the third step : contact your lifting specialist! He or she will work with you to analyze your options and help you find the best configuration for your specific needs. This will help you avoid the unpleasant surprises of installing equipment that doesn't correspond to your real needs, wasting both time and money.

Once all this information is gathered, you're ready for the third step : contact your lifting specialist! He or she will work with you to analyze your options and help you find the best configuration for your specific needs. This will help you avoid the unpleasant surprises of installing equipment that doesn't correspond to your real needs, wasting both time and money.

Already gathered all the relevant information? Premium Industrial Group will be happy to help you with your project.

We offer you 2 options :

Option A : Budget overview

If you'd first like to have an overview of the total cost of your project, so that you can assess whether it fits within your budget, you can consult the " How much does an overhead crane cost? " page. With the information you've gathered, you can easily calculate a realistic price range and compare it to your budget.

Option B: Contact a specialist

If you'd like to configure your overhead crane to get a precise quotation that suits your needs, you're ready to talk to a lifting expert. If you wish, you can fill in the form at the bottom of the page, and one of our Premium Industrial Group specialists will contact you within 24 hours.

We look forward to helping you make your lifting equipment purchase a success!

Technical representative at Premium Industrial Group inc.

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.