-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

Capacity restriction on overhead crane structure : 3 solutions

9:46

By Marc-André Martineau

Manager & Partner at Premium Industrial Group

In short…

There are spacing constraints between overhead cranes when the combined capacity of the equipment exceeds the permissible limit of the runway.

The article discusses 3 solutions to face this issue :

- Electrical or mechanical spacing

- Load management or load sharing

- Structural reinforcement

It also discusses their applications, advantages and limitations.

Read the article to find out more!

Last updated: December 4, 2025

Capacity restriction on overhead crane structure : 3 solutions

You need a new overhead crane to support your company's growth. You want to install it on the same runway as another of your overhead cranes.

Following the advice in the article Adding an overhead crane: the 3 essential checks, you consult an engineer, who informs you that the project it possible, but that restrictions will be involved.

The project is already getting complicated and you're starting to worry! You can see a bill increasing on the horizon, or your growth plans slowing down.

Will you be able to achieve your goals?

Are there solutions that would allow you to avoid replacing your structure with one of greater capacity?

Don't worry, this situation is quite common. In fact, approximately 30% to 40% of installations involving multiple overhead cranes have capacity restrictions on the structure.

In this article, we provide you with three main solutions :

- Electrical or mechanical spacing

- Load management or load sharing

- Structural reinforcement

You will discover the circumstances in which these solutions can be applied, as well as their advantages and limitations.

Note that some solutions offer more flexibility than others, and that all of these options are available for any overhead crane brand. You just need to find the one that's right for you.

Solution 1 - electrical or mechanical spacing

What is electrical or mechanical spacing

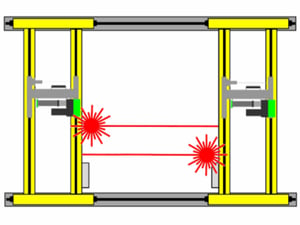

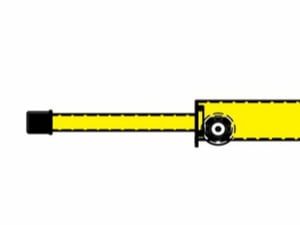

A solution that maintains a distance between two overhead cranes using a mechanical part or an electrical system. The latter usually consists of laser sensors that detect the distance between two overhead cranes to prevent them from coming closer than a predefined distance.

When does this apply?

When the engineer's assessment allows for the addition of an overhead crane on the same runway, there is often a distance that must be maintained between the lifting devices so as not to overload the structure. When this distance is acceptable for your operations, it’s a very good choice.

Electrical vs mechanical spacing

Advantages

Low cost, easy to install. The electrical system can be temporarily deactivated if necessary.

Limitations

Since overhead cranes must maintain a distance, this could limit certain operations, particularly tandem operations (see the article " What are the advantages of tandem lifting? ").

|

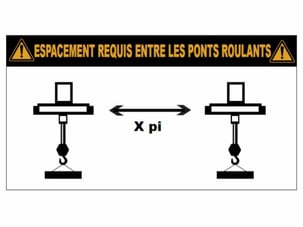

Warning sign: the basis for your safety If there is a capacity restriction on your structure, it must be displayed to ensure safe lifting operations. It's important to display the required distance between overhead cranes at all times, in accordance with the engineer's guidelines. A large warning sign, visible to operators, foremen, and management, can be installed directly on the overhead cranes. This warning will serve as a safety reminder for all stakeholders. |

Solution 2 – load management and load sharing

What is load management or load sharing?

Systems that prevent overhead cranes from exceeding the capacity of the structure. These systems can be relatively simple or complex, depending on your needs.

A very good example is the shared load system.

Shared load management

An intelligent system that controls the movement of overhead cranes based on the sum of the loads lifted by the lifting devices. When the combined total of the lifted weight exceeds the capacity of the structure, the overhead cranes cannot approach each other.

To better visualize this concept, watch the video "Load Management - A Solution from the Premium Industrial Group.

When does this apply?

These systems apply when overhead cranes need to be brought closer together, provided that the combined capacity of the loads lifted does not exceed the capacity of the structure. Here is an example illustrating shared load management.

Example of shared load usage

Installation : 2 10-ton overhead cranes on a 10-ton structure

Circumstances : A spacing of 20' is required by engineering, but the two overhead cranes must be able to move closer together when the sum of their lifted loads does not exceed the capacity of the structure.¹

System : An electric load sharing system is installed on the two overhead cranes. When it detects that the combined load of the two overhead cranes exceeds 10 tons (e.g., 8 tons + 4 tons = 12 tons), the system is activated and the two pieces of equipment cannot move closer than 20 feet. However, when the detected sum is lower (e.g., 6 tons + 4 tons = 10 tons), the system that prevented the overhead cranes from approaching each other is deactivated.

Why this is necessary : to ensure that the 20' spacing is always maintained when the total load exceeds the capacity of the structure. Safety is therefore enhanced.

Why this is necessary : to ensure that the 20' spacing is always maintained when the total load exceeds the capacity of the structure. Safety is therefore enhanced.

Advantages

- Offers a greater flexibility than solution 1

- Allows tandem lifting

- Cost often lower than structural reinforcement (see solution 3).

Limitations

Does not allow overhead cranes to be used at their maximum capacity simultaneously within the restricted area.

Do the solutions implemented to address structural restrictions relieve the operator and the employer of their responsibilities?

The systems described above are designed to assist the operator and provide additional protection. However, they do not exempt the operator from their safety obligations. It's crucial that the operator always knows the weight being lifted by the equipment they are controlling (see Article 248 RSST).

And let us recall that the AOHS, in its section 51, requires the employer to implement concrete measures to protect workers against risks related to equipment, buildings, and processes used.

Additional tools can also complement the proposed solutions to further enhance safety. For example, load indicators can display in real time the weight being lifted by the hoisting device.

Solution 3 – structural reinforcement

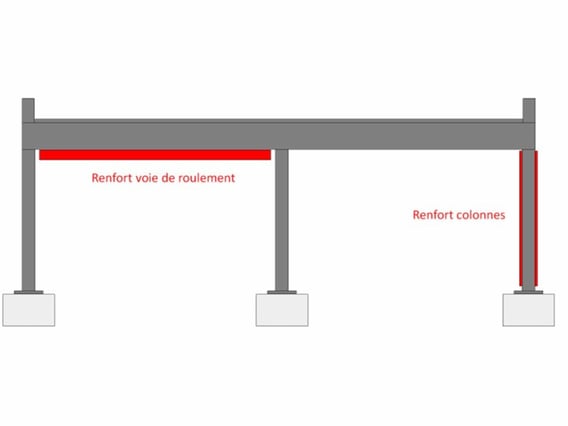

What is structural reinforcement?

Physical modifications to the structure in order to reinforce it. These modifications can take different forms depending on the engineer's requirements and must be carried out by a company that holds an RBQ license (see the article " Is an RBQ license required to install an overhead crane in Quebec? ").

When does this apply?

When it is not possible to add an overhead crane to the structure or when the spacing restriction established by the engineer hinders operations too much despite solutions 1 and 2.

Advantages

It's often possible to reduce or eliminate any spacing restrictions, providing total flexibility.

Limitations

In this case, a larger investment is often required. However, it may happen that reinforcing the structure does not allow the desired capacity to be achieved.

Summary of the 3 solutions

| Solution | Description | Overhead cranes as close together as possible | Management of capacity lifted by the overhead cranes | Price range |

| 1. Electrical or mechanical spacing | Laser sensor system | ✓ with bypass option | By the operator if bypassed | $2 500 to $3 500 |

| Extension on end carriage | x | N/A | $3000 to $5 0002 |

|

| 2. Load management or load sharing | Intelligent system that calculates the total load and limits movement if necessary. | ✓ | Through the system | $20 000 to $40 000 |

| 3. Structural reinforcement | Engineering and structural modification | ✓ | N/A | $$$3 (variable) |

Assess your needs to make the right choice

It can be worrying to learn from your engineer that your current structure cannot accommodate a new overhead crane without imposing restrictions. But you now have three solutions to deal with this situation, which can save you from spending large sums of money or complicating your growth.

Now with all these tools at your disposal, what should you do? You need to carefully assess your actual lifting and proximity needs for your overhead cranes that will be located on the same runway.

To do this, you can refer to the article " Need an overhead crane: Where to start? ". It will help you evaluate your application and guide you toward the information you need to gather, especially when adding an overhead crane. You can then contact your lifting specialist, who can analyze your needs with you and guide you toward the right solution.

The Premium Industrial Group has installed several of these solutions for various customers. For an example, see the article " Spectra Premium: Load sharing between overhead cranes ". Feel free to contact us by clicking on "Contact a specialist" at the bottom of this page. We can help you make the right choice.

Manager and partner at Premium Industrial Group

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.