-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

“I’d like to replace my hoist” : 5 checks for your satisfaction

5:19

Industrial machines may be solid and reliable, but they don’t last forever. At some point, you have to think about replacing them. This is also true of lifting equipment, such as wire rope hoists or chain hoists. In many plants across Canada, these hoists are beginning to age. They have to be replaced, either because they have exceeded the manufacturer’s recommended service life, because they cost too much to maintain or because replacement parts are no longer available.

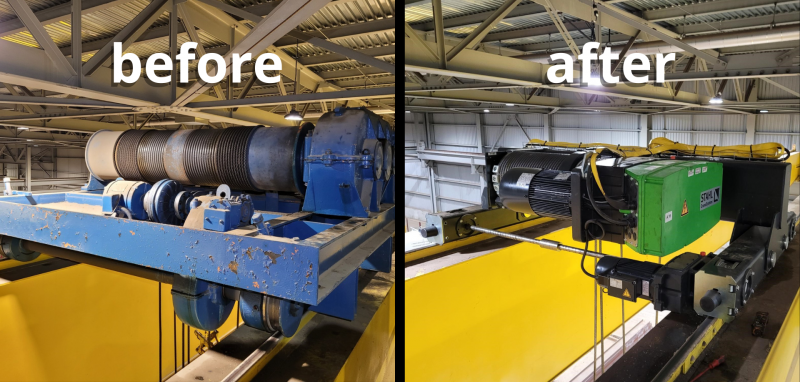

Your hoist has served you well for years, but it’s time for a new look? Premium Industrial Group has replaced over a hundred hoists in various companies. But what checks do you need to make to avoid unpleasant surprises? Is identical equipment always the best choice? The answers to these questions will help you ensure a safe and appropriate installation.

In this article, we’ll show you how to replace your hoist the right way, so you can be sure you’re choosing the right machine for your current and future needs. With this method, you’ll be able to resume production with complete confidence !

Here are the 5 steps to follow before replacing a hoist :

- 1. Check the general condition of the overhead crane

- 2. Analyze current and future lifting needs

- 3. Take corrective action based on these needs

- 4. Plan replacement carefully

- 5. Ensure safe start-up

1. What checks should be carried out on your lifting equipment before replacing the hoist?

First step: make sure that the lifting equipment (overhead crane, monorail, jib crane, etc.) on which your hoist is installed is in good condition and complies with safety standards. Your supplier will want to know the brand of the overhead crane, as manufacturers must follow strict safety rules. If the manufacturer is not recognized, your lifting equipment may not meet modern standards. In this case, it’s recommended to have the overhead crane checked by an engineer.

If the manufacturer is recognized, an engineering plan should be available, as this document must be kept by the equipment owner in the logbook. But if not, it’s best to ask an engineer to evaluate the overhead crane. This verifies the crane’s capacity and updates the information.

However, in the case of an overhead crane of a recognized brand, the condition of the equipment can be verified by means of a recent inspection report, if available. Your supplier can use this to determine whether the overhead crane needs to be repaired before the hoist is replaced. If not, a full inspection will be necessary. Once the condition of the lifting equipment is deemed good, the hoist replacement can begin. But is it always wise to choose an identical model?

2. Why analyze needs before replacing a hoist ?

Today’s equipment was probably chosen to meet the needs of a bygone era. But are today’s needs the same as before? For example, should lifting capacity be higher? Would it be better to have two hoists working in tandem, rather than just one? If your plant has changed or grown, your needs may have evolved. Taking the time to think about these needs and discuss them with your lifting expert will help you make the right choice.

To find out what information you might need before making your choice, some of the ideas in the article Are wire rope hoists preferable to chain hoists? What are the differences? may be helpful.

3. Adjustments to make to install your new hoist

A new hoist may require some technical adjustments. For example, is the overhead crane wiring compatible with the new equipment? Perhaps the replacement hoist has two speeds, whereas the old one had only one. The number of conductors in the electrical cables will no longer be the same. Has the type of control for the equipment changed from pendant cable control to remote control after the needs analysis?

What’s more, some older equipment doesn’t have grounding conductors, which are now mandatory. If your installation doesn’t have one, you’ll need to add one to meet current standards.

In short, some electrical components may need to be adjusted to meet new requirements. Some mechanical components may also need to be checked, such as beam dimensions and end stops.

Once all these checks have been made, what else should be planned for the replacement day?

4. How do I plan a hoist replacement?

Good planning is essential. The installation team must assess the site and the precise location of the replacement. In general, a lifting platform may suffice. But in some cases, a crane or special equipment is required, especially if the hoist is at height or difficult to access. Failure to provide this equipment could cause problems during the project and slow down your production.

5. How do I safely start up the new hoist ?

When replacing a hoist, it’s not enough to simply install the new one in place of the old one. An inspection and load test are required in accordance with current standards. These reports must be added to the equipment logbook.

Get started !

Now you’re ready to use your new equipment safely to achieve your production goals. Fill in the form at the bottom of the page to contact our experts and organize your hoist replacement in 5 easy steps.

Représentant technique chez Groupe Industriel Premium inc.

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.