-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

Adding an overhead crane : the 3 essential checks

6:32

When demands increase and production has to keep pace, it sometimes becomes necessary to replace or add new equipment to meet requirements. This includes overhead cranes. Premium Industrial Group has helped a number of companies safely add overhead cranes ot existing structures.

In this context, a question frequently comes up: ”Is it safe to add an overhead crane of the same capacity to my runway track? “ For example, a customer might think :”I have a track equipped with a ten-ton overhead crane; surely I can add a second ten-ton overhead crane? But is it really that simple? Are there any risks involved in increasing the number of lifting equipment on the same track? For growing companies, these questions are crucial.

In this article, we will outline the three essential checks to ensure the safe addition of an overhead crane. It is important to note that these same checks also apply when replacing an overhead crane. By following these steps, you can move forward with confidence in your project and select the right experts to support you.

But to start, let’s talk about the capacity of the structure.

Why check the structure’s capacity before adding an overhead crane?

If the new lifting equipment has a greater capacity than the existing one, it seems obvious to ensure that the structure will be able to support the additional weight. Unless this has been foreseen at the design stage, only an engineer will be able to tell whether the structure is strong enough to take the new overhead crane. It may even be necessary to reinforce the structure to ensure compliance.

Who is responsible for verifying that the runway can support a new overhead crane?

Occasionally, the documentation regarding the structure might not be available, or we might believe it to be "strong enough." The CSA B167-16 standard, article 7.2.1, reminds us that "The runway and the supporting structure of the lifting device are considered an integral part of the building and are therefore subject to the requirements of the building code." The standard continues by explaining that it is the owner's responsibility to "know the requirements" and "obtain the necessary approvals" related to the structure.

It is important to emphasize that the framework Act (AOHS, chapter S‑2.1) strengthens this responsibility in its section 51, which requires the employer to ensure the protection of workers against risks related to equipment, buildings, and any process used.

But why bother if the capacity of the new overhead crane is equivalent or inferior to that already in place? It all depends on the initial design of the structure. Sometimes, the structure is designed for just one overhead crane, or for several, but with a specific distance between them. The distance between overhead cranes can be significant to avoid overloading the structure in the same place.

Incidentally, if the future use of a second overhead crane with spacing doesn’t interfere with operations, it may be worth planning for it, as the cost of constructing a building including this configuration is relatively economical. But in any case, only an engineer can define these criteria to ensure the safety and solidity of the installation.

That said, some might think: “The two overhead cranes will never operate at the same time or side by side; each will be used at one end of the track.” But that’s not enough to guarantee safety. An accident often involves an “unforeseen event” that could have been anticipated. The “never” can quickly become a “once”, leading to serious consequences for people and equipment.

That’s why it’s essential to check the capacity before putting another overhead crane on the same track.

Let’s take a look at the 3 elements to check before adding an overhead crane, starting with the capacity.

1 – How to check structural capacity before adding an overhead crane

Step 1 : Consult plans or perform an engineering analysis

First, check the engineering drawings, which show the structure’s capacity. If these documents cannot be found, you may need to contact the company that carried out the work. Where no plans are available, an engineering analysis will determine the capacity and criteria required for the addition.

Step 2 : Analyse technical specifications

Example of a table showing overhead crane specifications on an engineering drawing

If the capacity of the new equipment is equal to or inferior to the structure’s, it does not guarantee it can be added without restrictions. Check the overhead crane’s specifications: sometimes, a table indicates whether the structure can accommodate another piece of equipment, while specifying the spacing to be respected between the overhead cranes (see the following table). This distance must be ensured by installing devices to maintain a safe distance, such as mechanical or electronic systems.

2 – How to check the conductor bars system before adding an overhead crane

The electrical system for the runway tracks is designed for the current installation. Adding another overhead crane could exceed this electrical capacity. This could lead to problems such as motor overheating. It is therefore important to check that the conductor bars have the necessary capacity.

Will voltage losses still be acceptable with the addition of an overhead crane?

Any power supply can lose a little power when feeding equipment. But by adding another crane, this may no longer be acceptable. You could then add a new power point, or even install a parallel system.

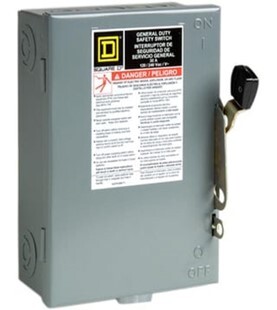

3 – How to check the power supply isolator before adding an overhead crane

Each overhead crane is fitted with a circuit breaker to cut off power in the event of a problem. However, it was designed for a single unit. If another is added, the circuit breaker may no longer be adequate. You may need to adjust the fuse and cable ratings, which only a master electrician is authorized to do.

To make a success of your overhead crane addition project

To successfully add an overhead crane to an existing structure, follow these steps :

- 1. Analyze the building plans and crane specifications to assess the feasibility of an addition and determine the spacing distances, if applicable.

- 2. Confirm conductor bars capacity and check power losses.

- 3. Examine circuit breaker with a master electrician.

Adding lifting equipment to the same track is not as simple as it sounds. That’s why we recommend calling in the professionals.

Who can help you?

Here is a table of experts who can help you check the different elements to consider :

|

Verification element

|

Professional |

Overhead crane supplier assistance

|

|

Capacity

|

Contractor, engineer or outside firm

|

Provide capacity data and modification costs if necessary.

|

|

Conductor bar ratings

|

Overhead crane supplier

|

Check and evaluate for adequate electrical capacity and voltage losses. Provide modification cost.

|

|

Power supply isolator

|

Master electrician

|

Provide an electrical load estimate for the power supply isolator.

|

Do you have an overhead crane project in mind?

Adding another crane can be complex, but you’re not alone! If you have a project of this type, Premium Industrial Group is here to serve you to ensure the safety of your installation. Contact us for a free consultation by filling out the quote form at the bottom of the page.

If you would like to know more about runway track reinforcement, please visit the following page of our partner Premium Industrial Structures : https://structuresindustriellespremium.com/en/services/crane-runway-reinforcement// .

Manager and partner at Premium Industrial Group

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.