-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

Overhead cranes types: Girder vs. Box girder. Which one to choose?

6:07

In short…

There are 2 types of overhead crane frame :

- Girder overhead crane

- Box girder overhead crane

This article compares the two types in order to understand where they are used and what the advantages of each are. This comparison will enable you to determine which one best suits your needs.

Girder or box girder cranes: How does this affect you?

“It makes no difference to me,” you might think.

It’s true that, in some cases, the choice will be easy. But in other cases, knowing their differences will be important, because each has its own advantages. You wouldn’t want to select the wrong type of overhead crane and have regrets!

After reading this article, you’ll know the differences between a girder crane and a box girder crane. But most of all, you’ll know the advantages of each, and which one to choose according to your situation.

Girder overhead cranes: application, pros and cons

The girder crane is manufactured with a steel master girder ordered as is from a supplier. It can be made of a single beam (single girder), or two beams (double girder).

If your overhead crane has a span of less than 55ft or a rated capacity of less than 25 tons, your crane will generally be made with a beam. Why? Because it costs less. It’s a standard piece of steel available from suppliers’ catalogs. for the same reason, its delivery time is usually shorter. What’s more, a girder is generally smaller than a box girder, which can increase lifting height

Poutre

A girder crane can also be built up to a span of around 65ft. However, between 55ft and 65ft, the overhead crane will be “softer”, i.e. it will bend slightly, creating rocking and swaying effects when lifting and moving a part (see the box Deflection and its impact). This movement can be detrimental to operations requiring precision or rapid speed, as well as operations involving repeated stops/starts (jogging).

Deflection and its impact

The longer the crane girder, the more it bends under the weight of the load. This vertical movement is known as deflection.

As a result, when the hoist is raised or lowered, stops and starts can cause a vertical back-and-forth movement known as oscillation. The effect is a little like a taut rope to which a force is applied and then released: it will start to vibrate up and down.

This oscillation is obviously transmitted to the part being lifted, and can complicate maneuvers. For instance, workpieces need to be stabilized before they are set down.

the oscillation phenomenon is more pronounced on a girder crane than on a box girder crane. Why is this? Because the design standards for maximum deflection are not the same for girders as for box girders.

Box girder cranes: application, pros and cons

A box girder consists of steel plates joined together to form a rectangular master beam. Unlike a standard beam, it is made to measure. Here again, the overhead crane can be single or double box girder.

In general, an overhead crane will be made with a box girder when it has a span of over 65ft or a rated capacity of over 30 000kg.

In addition to providing a longer reach or higher rated capacity, a box girder crane may be the right choice if your crane’s reach is in the overlap zone, i.e. between 55ft and 65ft. For more precise operations, it will be more stable due to its greater rigidity.

Box girder

Sometimes, the box girder crane can be useful if heavy or larger components need to be installed on the crane frame. A standard girder may not be suitable.

What are the disadvantages of this type of overhead crane?

Firstly, it’s more expensive because of the manpower required to assemble it. As an indication, for an overhead crane with a span of around 60ft, you need to add around ten thousand dollars per box girder compared with a beam. What’s more, it can take longer to manufacture. And lastly, its design could make it taller, resulting in a loss of lifting height.

What is the overlap zone?

In this article, the overlap zone represents the span range within which both a box girder and a girder crane can be manufactured. This overlap zone is usually between 55ft and 65ft.

How to choose between a girder crane and a box girder crane

In this article, you’ve learned the difference between girder and box girder crane frames, and in what cases they’re typically used. You’ve also learned about the pros and cons of each. See the following table for a summary of these points.

| Girder overhead crane | Box girder overhead crane | |

|---|---|---|

|

Can be single or double

|

✓

|

✓

|

|

Master beam availability

|

Supplier's catalog

|

Supplier's catalog

|

|

Span

|

Up to 65ft

Selection will depend on the combination of span and capacity |

Can be over 65ft

Selection will depend on the combination of span and capacity |

|

Rated capacity

|

Up to 30 tons (double girder)

|

Up to 200 tons, and more…

|

|

Price

|

$

|

$$

|

|

Delivery times

|

Shorter

|

Longer

|

|

Lifting height

|

Maximal

|

Slight loss

|

|

Larger or heavier components to be installed on the crane

|

Less possibilities

|

More possibilities

|

But how can you choose the right crane for YOU? First and foremost, it’s the application that will determine the best choice. Then, certain advantages or disadvantages may influence your decision, such as the price difference or the lifting height.

For example, if you need an overhead crane for intensive use, fast lifting speeds (over 6 m/min) or a magnet-equipped overhead crane, a box girder crane is recommended. But for a mechanical workshop or occasional use, a girder crane will generally be acceptable.

Here are a few more concrete examples to help you:

First example : In the plastics industry, a 60ft overhead crane has to take molds out of a machine to service it. Putting this mold back in place will require precision. A buyer may decide to choose the box girder crane for its stability.

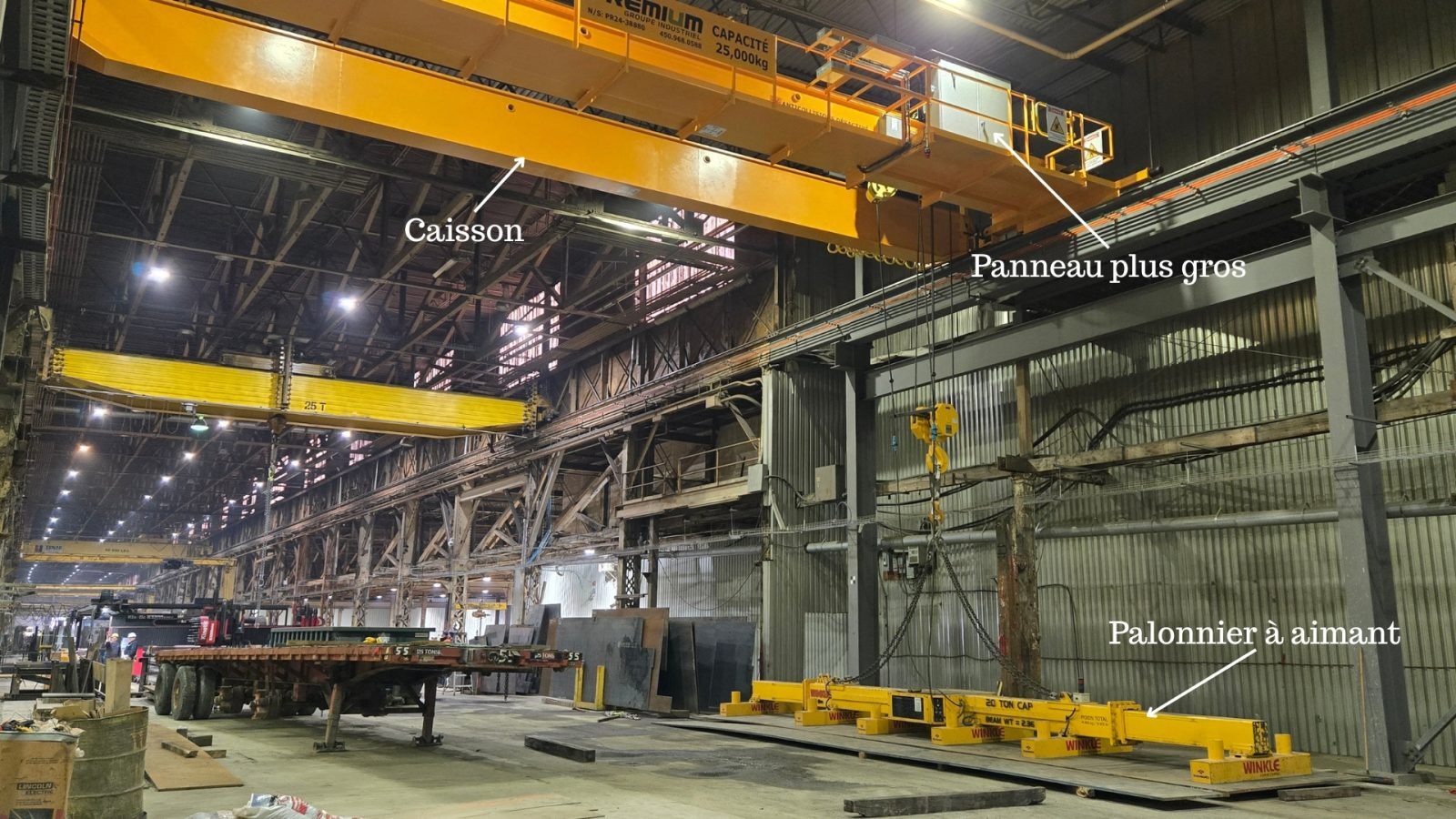

Second example : a 60ft overhead crane handles long steel sheets with a magnet spreader bar. It is used intensively. This application requires good stability so that the sheets don’t wobble when placed on the cutting table. This application also requires a larger electrical panel, and sometimes additional batteries, which will have to be installed high up on the crane frame. In this situation, a box girder crane is a better option than a girder crane.

Premium Industrial Group specializes in the manufacture of all types of overhead cranes, both girder and box girder cranes. Our advisers will be happy to analyze your application with you and recommend the right solution. Don’t hesitate to contact your specialist to help you analyze these options.

Technical representative at Premium Industrial Premium

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.