-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

What are the advantages of tandem lifting?

6:34

When it comes to overhead cranes, tandem lifting has become increasingly popular. But, truth is, this method is not new. With technological advances, this technique has evolved and is not quite the same as it was when I started my career 18 years ago!

Do you have lifting height constraints? Do you face stability problems when lifting your parts? Do you have more complex lifting operations to perform? If you answer yes to any of these questions, it may bring a host of unpleasant complications into your operations. However, depending on your situation, twin lifts may be an effective solution to these problems. But what exactly is this technique? How does it really work? What are the applications and benefits for today’s industries?

In this article, you’ll discover the modern approach to tandem lifting, how it works and how it can be used in different situations. After reading, you’ll have all the information you need to decide whether this method could help you optimize your operations.

What is tandem lifting ?

The term tandem lifting is used when a load is lifted with more than one piece of equipment simultaneously. In the past, several operators had to coordinate their actions, which increased the risks. But today, thanks to technology, a single operator can control several pieces of equipment at the same time with a single transmitter. This includes the possibility of using three or four devices, or even more.

How does tandem lifting work today ?

The modern version of a tandem lift is based on the use of a single transmitter that controls several pieces of equipment simultaneously. Although the selection method may vary, the operator can turn on several lifting devices by activating a command on the transmitter.

However, although tandem lifting is safer today, there are still risks involved that need to be mastered. To learn more about these risks and how to use this technique safely, we recommend reading the article “Is tandem lifting dangerous? Master its unexpected dangers!“

Used with caution, this method can be employed in a variety of applications, where it is a valuable asset. Let’s take a look at these possibilities.

Tandem lifting applications and how they benefit you

While it’s true that tandem lifting involves unsuspected risks, it also brings unsuspected advantages. Here are just a few applications of tandem lifting that demonstrate the possibilities this method has to offer.

Application 1 : safe, compliant lifting of parts too heavy for a single piece of equipment

The first simple application is when the object being lifted is too heavy for a single piece of equipment. The use of two overhead cranes ensures safe weight distribution.

Application 2 : safe lifting of parts too long or too large for a single piece of equipment

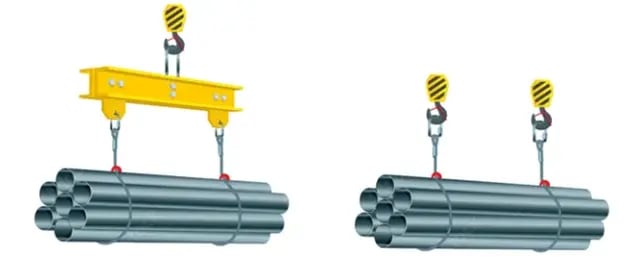

The second application is when the workpiece is too long or too large to be lifted by a single lifting device. In this case, the load would start to sway and threaten to topple over due to the lack of stability, making it virtually impossible to handle. With several pieces of equipment, you get several anchoring points on the part, which stabilizes the load. This kind of application is frequently seen in steel yards, but also in other sectors. For an example of this application, see the case study “Machinex: Mastery of tandem lifting” .

Application 3 : handling requiring additional lifting height by eliminating the accessory below the hook

In some cases, the handling of certain parts requires the use of slings (cables or chains) or expensive and complex accessories suspended from the hook. As a result, these accessories reduce lifting height (to find out more, read the article “The 5 solutions to increase the lifting height“) However, it is sometimes possible to replace these accessories by using several hoists in tandem. This way, the hooks can be attached directly to the anchor points (the places where the hook is fixed onto the workpiece), eliminating the need for an accessory. What’s more, this will increase the flexibility and the number of options for attaching the hook to the workpiece (see the illustration below).

Application 4 : productivity and stability of parts with anchor points at different levels

Some parts are complex, involving anchor points at different heights. These configurations sometimes make slinging complex and arduous, which can affect part stability and operational productivity. Here again, thanks to a tandem lifting approach, the lifting hooks attach directly to the anchor points. This speeds up the attachment procedure and offers greater lifting stability. The result is greater efficiency and safety.

Application 5 : safe turning of parts

Turning a heavy load involves significant safety risks. But these risks are much higher if only one piece of lifting equipment is used. With the right technique, the use of at least 2 hoists allows for a better control of part turning, as shown in the following video.

Premium Industrial Group regularly uses this technique to turn beams or boxes during the manufacturing of overhead cranes. This handling facilitates production work, particularly for welders who do not have to bend and adopt an uncomfortable position in their work. This method is also commonly found in the machining and pressure molding industries (die-casting).

How do you know if tandem lifting is right for your operations?

Now you know in which situations tandem lifting can be advantageous. As you read this article, you may have thought of some of your operations where this approach would be useful. Indeed, when tandem lifting is done properly, using modern safety practices, it can simplify your lifting and save you a lot of headaches. Whether you need to lift heavy or long parts, gain lifting height or stability, or for a turning maneuver, tandem lifting is an advantageous approach in many respects.

To determine whether this mode of operation can be applied to your lift, read the article “Need an overhead crane: Where to start?” which will help you analyze your needs. With all this information in hand, you’ll be ready to talk to your lifting specialist, who will be able to advise you on the right solution for your needs. If you wish, you can consult one of our specialists by filling in the form at the bottom of this page.

Upgrading equipment to tandem mode

A single-hoist overhead crane can be upgraded to a double-hoist so that it can be used for tandem lifts. It is often not necessary to completely replace the equipment.

Example: an owner has a 10T overhead crane and would like to convert it into a 2 x 5T overhead crane (crane with 2 5T hoists) in order to operate in tandem. It will be possible to recover the overhead crane itself, along with several components, and replace the 10T hoist with 2 x 5T hoists.

However, mechanical and electrical modifications will have to be made to the equipment at various levels.

Technical representative at Premium Industrial Premium

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.