-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

The top 10 safety options on an overhead crane

December 14, 2024

The top 10 safety options on an overhead crane

10:49

Safety is a top priority today. To avoid accidents in the workplace, many companies are stepping up their safety measures. Lifting is a sector that is particularly relevant. But what options are available to help you make your lifting operations safer?

Premium Industrial Group, which sells between 200 and 250 overhead cranes a year, has installed many of these options over the years. But I’ve found that buyers are often unaware of these solutions. It would be unfortunate if an accident were to occur when a solution was available to prevent it. That’s why we present here the top 10 most common safety options on an overhead crane. After reading this article, you’ll know which safety options apply in the most common situations. You’ll then be able to determine which ones are right for you, to ensure the safety of your workers.

1. The spare remote control

What is it?

The remote control is used to control the overhead crane from a distance. Today, the wireless version is the most common. But if it fails, you need to be able to replace it quickly to continue operations.

Wireless control manufacturers have different strategies when supplying this type of system. Some include 2 remotes as standard for the same overhead crane. Others offer just one, but one that can be coupled to several cranes. In all cases, the important thing is to make sure you use a 2nd transmitter safely.

How does this option make your operations safer?

When the main remote control breaks down, the spare one allows you to regain control of your lift and avoid potentially dangerous situations. A load that remains suspended longer than necessary becomes a source of danger for workers.

However, managing the 2nd remote control is also a crucial safety aspect, as some models can be activated at the same time as the main remote control. Imagine the danger of using a 2nd remote control at the same time as the main one!

2. The anti-collision system

What is it?

This is a system of lasers whose function is to prevent overhead cranes from colliding with each other at full speed. When the system detects the arrival of the other crane, it switches to low speed, and then stops.

How does this option make your operations safer?

Lifting loads can lead to dangerous swaying, source of accidents. The operator must therefore keep it under control at all times. With two overhead cranes on the same track, the risk of collision increases, leading to unexpected sway and accidents. The anti-collision system reduces this risk by slowing or stopping the overhead crane, thus limiting sway and accidents.

3. The end of travel limit switch

What is it?

This is a generally mechanical device designed to prevent the overhead crane or hoist cart from hitting the end stop at full speed. As the overhead crane approaches the end of the runway, a mechanism is activated to reduce speed. The objective is therefore similar to the anti-collision system.

This device is generally standard for overhead crane travel. However, for cart travel, check whether tandem operations (two hoists simultaneously) are planned, as limit switch systems can pose safety problems in this case. For more information, see our article How much do you know about the hidden dangers of tandem lifting?.

How does this option make your operations safer?

The safety benefits are similar to those of the anti-collision system mentioned above, except that the protection is located at the ends of the track rather than between two overhead cranes.

That said, this system also offers other advantages that are less related to safety but still interesting. The end-of-travel limit prevents the motor, and thus the wheels, from continuing to turn when the overhead crane or trolley reaches the end stop. This extends the lifespan of the wheels and rails by reducing wear due to friction. Additionally, it prevents the overhead crane or trolley from hitting the end stops at full speed, thereby reducing the movement of the runway and the risk of damage.

4. The rotating beacon

What is it?

The rotating beacon is essentially a light installed on the overhead crane, often orange, which flashes to indicate that the crane is in motion. It’s an optional accessory, although it may be mandatory in certain types of industry, such as foundries.

How does this option make your operations safer?

The flashing light of the moving overhead crane alerts workers that a lifting device is in operation. This reduces the risk of accidents due to inattention.

5. Load display

What is it?

This is an electronic device that displays the load the hoist is lifting in real time. The weight can be clearly displayed on a screen, with an accuracy of 2% to 5% of the hoist’s rated capacity. You can choose your unit of measurement (lb, kg, tons).

How does this option make your operations safer?

Lifting equipment has a capacity limit. Exceeding this limit can lead to collapse, resulting in major damage or injury. That’s why the maximum capacity of the equipment must always be displayed. But the electronic load display increases the level of safety by monitoring the load being lifted in real time. This reduces the risk of lifting parts that are too heavy for the equipment, or mechanically jammed. Note, however, that it is always the operator’s responsibility to know the weight of the part he is lifting.

6. Lighting

What is it?

This is an LED light system installed directly under the overhead crane or hoist girder to improve ground lighting. This is useful when the overhead crane is partially blocking the light from the building, thus reducing the brightness at ground level. Note that this option is also used outdoors.

How does this option make your operations safer?

Depending on the operation and configuration of the building, this additional lighting system can help prevent accidents caused by a lack of visibility during certain operations.

7. The maintenance bridge

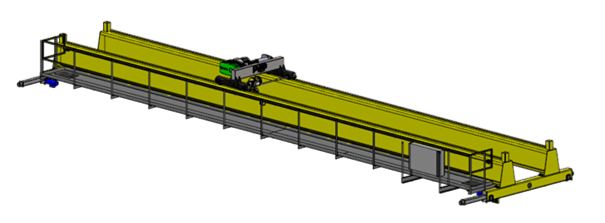

What is it?

These are platforms with railings, usually attached to a double girder overhead crane. They can take a variety of shapes and be placed in different locations, with different types of flooring. It provides access to lifting equipment for maintenance of certain components. Accessories such as fall arrest systems or engine access hatches can also be added.

How does this option make your operations safer?

The walkway facilitates maintenance in complete safety, offering easy access along the entire length of the overhead crane. Once the overhead crane has been disconnected from the power supply and padlocked, maintenance can be carried out in complete safety, without the risk of electrical accidents or hazards associated with lifting platforms, such as collisions with moving vehicles.

8. Temporary bumpers

What is it?

A temporary bumper is an easy-to-install, easy-to-remove mechanical device on a runway track. It is used to stop an overhead crane, enabling it to be isolated for maintenance, even if other lifting devices are on the same runway. It can also prevent an overhead crane from reaching an area where maintenance work is being carried out on building mechanics (garage doors, overhead lights, ventilation, etc.).

How does this option make your operations safer?

When a worker is performing maintenance on an overhead crane, the presence of other cranes in the same track can create a risk of accident. Another piece of equipment could collide with the one being serviced, endangering safety. The temporary bumper isolates the overhead crane undergoing maintenance, preventing it from colliding with other cranes. Similarly, when maintenance work is being carried out on garage doors or other building equipment located close to the runway tracks, temporary bumpers protect workers from overhead crane movements.

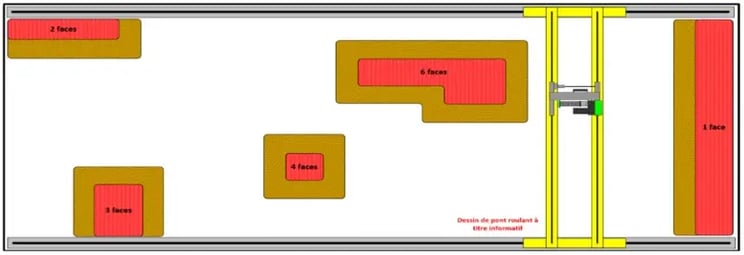

9. The zoning system

What is it?

It’s a solution made up of sensors and controllers that can be used to program no-go zones for the overhead crane. When the overhead crane approaches these zones, it will slow down and stop at the edge of the zone. This option is particularly useful when an overhead crane is installed in an area with several critical machines or frequently moving personnel.

How does this option make your operations safer?

Even if overhead crane operators are trained, mistakes can still occur. This system blocks the movement of a load towards an area where workers or machines are present, thus preventing collisions, damage and injury.

10. Security lights

What is it?

Not to be confused with the rotating beacon or LED lighting, the security light is a light directed at the ground to indicate overhead crane movement. It can be installed on the frame of the overhead crane or on the hoist. When installed on the overhead crane, it is static and indicates crane movement on the ground. When installed on the hoist, it tracks cart movements. There are several types available: projectors, laser in straight or grid pattern, etc.

How does this option make your operations safer?

This option takes safety to another level, providing a visual indicator not only of the device’s movement, but also of its exact location. Its use is often of interest on pedestrian walkways. However, some operators do not appreciate this option, which can be considered blinding.

OPTION

DANGER AVOIDED

SPARE TRANSMITTER

Suspended load

ANTI-COLLISION SYSTEM

Load sway

END OF TRAVEL LIMIT SWITCH

Load sway

ROTATING BEACON

Collision with a load

LOAD DISPLAY

Overload

LIGHTING

Lack of visibility

MAINTENANCE BRIDGE

Lack of access to components

TEMPORARY BUMPERS

Overhead crane collision

ZONING SYSTEM

Collision with a load

SECURITY LIGHTS

Collision with a load

Choose the right options for you

Now that you know about these security options, you have more information in your pocket. You can analyze your operations with these solutions in mind and identify the options that will increase security in your context.

It is important to note, however, that several of these options are more advantageous to integrate at the time of purchasing your crane. Once the equipment is installed, adding them can result in higher installation costs on site.

And if you haven’t found a solution to your security issue after reading this? These 10 options are just an overview. To determine the right solution, have your needs analyzed by a specialist. The article “I need an overhead crane!” What information do I need to pass on to my supplier? will help you prepare for this important step.

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.