-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

Overhead cranes: 3 solutions for more safety and performance

10:59

In short…

Here you will discover 3 technological options that can enhance the performance or safety of your overhead cranes :

You’ll see in which applications they can be used, as well as their utility and limitations. You’ll be able to determine whether any of these options could be useful to you.

Have you ever thought to yourself: “If I had known it existed!” ?

Have you ever had a problem in front of you, but thought you’d just have to accept it and deal with it? Then, suddenly, you discover that, in fact, a solution did exist, but you didn’t know about it! This can happen, and it can be frustrating when it involves overhead crane performance and safety.

During my last 15 years at Premium, I’ve worked with some industries that had this type of challenge. They were surprised to find out about technologies that met their challenges, which increased their productivity or enhanced worker safety.

In this article, you’ll discover three often overlooked – yet accessible – technologies that could address problems you thought were unavoidable.

Here they are :

- 1. Load management

- 2. Anti-sway

- 3. Remote diagnostics

As you finish reading, you’ll know everything there is to know about these 3 technologies: their application, their utility and their limitations. You’ll then be able to determine how these intelligent technologies can be applied to your business.

1. Load management : avoid overloads and protect equipment

What is it?

It’s a technological system that enables 2 pieces of lifting equipment to “communicate” load information with each other, so as not to overload the equipment.

How load management prevents overloads – 2 concrete examples

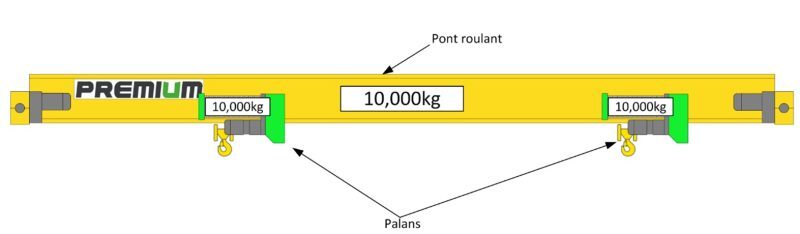

Application 1 : The sum of the rated capacities of the hoists exceeds the rated capacity of the overhead crane

In some work areas, it may be necessary to use two hoists on the same overhead crane to lift the maximum load (see article What are the advantages of tandem lifting? ). But at other times, we may only need one of these hoists to lift the same load.

Let’s illustrate: a 10,000 kg overhead crane, fitted with 2 hoists, is used to lift a part weighing around 10,000 kg. This part requires the use of both hoists. But in another area, another part, also weighing 10,000kg, must be lifted by a single hoist. If at least one of the 2 hoists can lift a 10,000kg load, this means that the sum of the 2 hoists exceeds the rated capacity of the crane itself. What is the solution?

Solution : load summation module on hoists

A load summation module can be installed on tandem hoists. This technology enables information to be exchanged between the 2 hoists to activate a load limiter based on the combined sum of the 2 loads. This feature prevents the crane’s rated capacity from being exceeded when the hoists are used in tandem, while allowing the full load to be lifted when only one hoist is used.

Application 2 : The sum of the rated capacities of the overhead cranes exceeds the rated capacity of the structure

In other circumstances, it’s the building structure itself that can’t support such a large load capacity in a confined space. For example, a building may have been designed for the installation of 2 20-ton overhead cranes, but the structure may not be able to support the 40-ton load side by side. This design severely limits the options available. Or the building is extended to accommodate a new 20-ton overhead crane on an existing crane runway, but the older section of the building is only designed to take a 10-ton load.

Solution : overhead crane positioning sensors

For structural limitations, sensors can monitor the positioning of overhead cranes in the factory and the actual combined weight of equipment operating in the same area. Thanks to communication between the 2 cranes, this system will prevent the equipment from overloading sections of the building but will also allow the 2 pieces of equipment to work in the same area when their combined capacity is safe. What’s more, the overhead crane will be restricted in its movement to an area where another piece of equipment is already operating at maximum load.

What will you gain by using load management?

These solutions bring great flexibility to operations, while maximizing available lifting space. The result is cost-effective use of lifting space and a corresponding increase in productivity. In terms of safety, it helps avoid human error, thus protecting personnel and equipment.

What are the limits of load management?

This system does not replace the responsibility of the operator, who always remains in charge of his load. This technology simply assists the operator. Just like the safety systems in cars: they assist the driver, but don’t replace him or her in guaranteeing safety.

After load management, let’s look at another frequent problem : load sway.

2. Avoid the dangers of load sway with anti-sway

What is it?

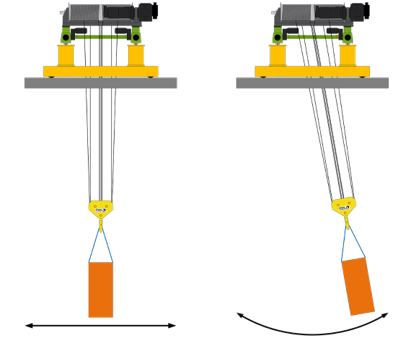

It’s a technology that greatly reduces the effect of load sway during handling.

Anti-sway to the rescue of less experienced operators

Controlling load sway requires experienced manpower. In some industries, maneuvers require constant attention and vigilance, leaving the operator vulnerable. When experienced operators are hard to find, or when staff turnover is more frequent, the risk of injury or breakage is higher. What’s more, a swaying load needs to be constantly stabilized, which results in a substantial waste of time at every move.

Solution : simulating sway with technology

By equipping the overhead crane with variable speed drives on the travel motions (see our article Do you need a variable speed drive on your overhead crane? The different types of motor and control. to find out more), it is possible to configure acceleration and deceleration algorithms proportional to the position of the load. This technology then simulates, automatically and without fail, the handling that an experienced operator would perform, stabilizing the load as much as possible during travel. This function can be activated or deactivated as required.

What will you gain by using anti-sway?

Here again, the result is optimum safety for workers and additional protection for the equipment. There is also an immediate gain in productivity during handling, as well as in the training time required by operators before they can handle this type of equipment.

What are the limits of anti-sway?

This solution is primarily intended for operators with limited experience with this type of load. Indeed, since the experienced operator is used to controlling the load himself, this feature could well hinder him and become an irritant. Hence the importance of being able to activate and deactivate the function.

Having seen a technologically advanced system, let’s see what new technologies have to offer with remote monitoring.

3. Remote monitoring : an access to your critical data… and more!

What is it?

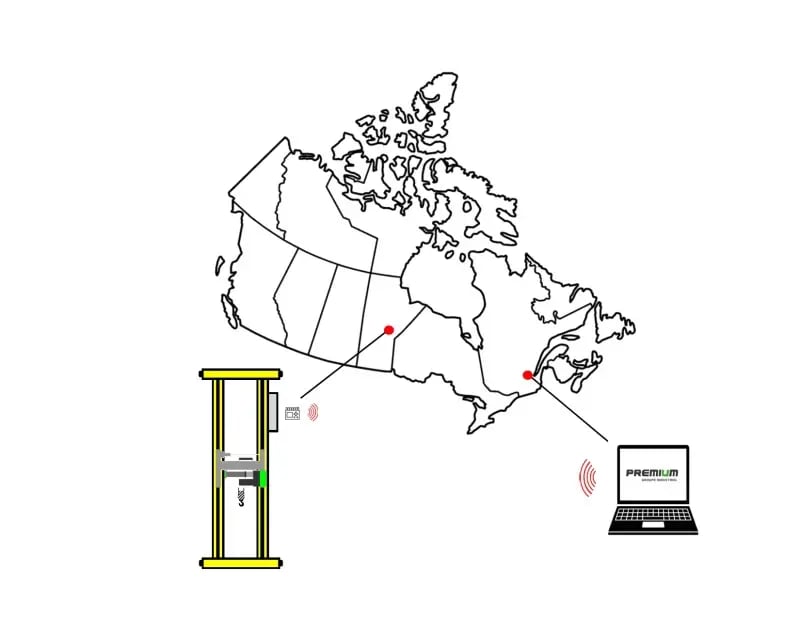

It’s a remote connectivity technology for receiving, reading, recording and even retransmitting data generated by the overhead crane’s electronic components.

Extracting the potential of technological equipment through remote access

Although the data available varies depending on the manufacturer, this solution offers access to a wide range of information, such as operating hours, number of lifts, overloads, stop/start frequency, error codes, etc.

This information is collected via the load limiter, the variable speed drive, motor thermal sensors or other electronic modules. Access to this data can be useful for a variety of applications.

For example, this could enable a technician to remotely analyze the data collected in order to establish a pre-diagnosis and consider possible solutions. For instance, he could bring potential replacement parts based on the data collected, and hope to solve the problem in a single visit.

Real-time data analysis can also be carried out to ensure the equipment’s performance.

In the case of complex equipment, these tools can also be used by the technical team to commission and adjust equipment, without the need to be physically on site.

Finally, some products can communicate information to the equipment owner via a cellular network (at an extra cost).

What will you gain by using a remote monitoring system?

The intervention of a technician in response to a service call generally entails a temporary production downtime required for investigation and diagnosis. What’s more, a second visit by the technician is often required to complete the repair. As a result, the repercussions of repeated equipment downtime can be frustrating, leading to an unexpected drop in productivity throughout the production chain.

Thanks to these new technologies, equipment maintenance is improved. Intervention times and production downtime can be reduced, which in turn can help boost productivity.

What are the limitations of the remote monitoring system?

Contrary to popular belief, this solution does not generate a service call to your maintenance provider. Nor is it a solution that allows you to see everything that’s going on with your machine in real time. It only provides access to certain predefined information, depending on the product.

What’s more, connectivity problems are not uncommon, whether due to lack of cellular coverage or interference with other machines. It has to be said that these are new technologies on the market which, like many others, will be optimized over time through updates and improvements.

Which is why it’s a good idea to research in depth the product you’re considering, i.e. check coverage areas, annual user fees and compare them with the conventional method of intervention.

Where do you start to increase your productivity or safety through technology?

The 3 technologies mentioned above are no longer unknown to you. You now know what load management, anti-sway and remote monitoring systems are. These solutions address the common challenges of overload, instability and extended downtime. Is there a problem you could solve right now with one of these options? Could productivity or safety be increased?

If so, your lifting solutions supplier will certainly be able to guide you and analyze the precise need with you. Premium Industrial Group’s mission is to keep innovating! We’d be delighted to advise you on your approach. Contact us by filling in the form at the bottom of the page, and a Premium specialist will guide you towards the technology best suited to your needs!

Manager and partner at Premium Industrial Group

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.