-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

How to properly maintain overhead cranes and how much it costs

7:34

In short…

Lifting equipment must be maintained according to a program that includes :

- Inspections

- Repairs

- Ajustements and lubrification.

This program must comply with the manufacturer’s instructions, as well as current standards and legislation. Interventions must be recorded with the date and remain accessible in case of need. Only qualified personnel may carry out this work. (CSA B167-16: 4.1.2, 6.1.3, 8.1.2, 8.3.1)

A good start to maintenance is inspection. There are 3 types of inspection :

- Operational inspection : before and after use.

- Frequent inspection : between daily and monthly, depending on the class.

- Periodic inspection : at least once a year, depending on the class.

These inspections enable short-, medium- and long-term repairs to be planned. The owner can then organize maintenance by priorities.

The cost of maintenance depends on :

- The cost of parts

- The cost of labor

- Technician travel costs.

The distance to be covered and the type of parts to be replaced influence the cost. See our page about prices for more details.

Read on to find out more… or fill in the form at the bottom of the page for help with your maintenance program!

Another machine to maintain! Yet another expense! When will we have self-maintaining machines? Although robotics, artificial intelligence and nanotechnology are making strides in this direction, we’re still a long way off. So in the meantime, maintaining your overhead crane remains a concern, and so do the associated costs.

Whether you’re the owner of a new piece of equipment, or have owned one for several years, are you concerned about the legal obligations and accident risks associated with poor maintenance? Or perhaps you’re wondering how much it will really cost to maintain it?

Premium Industrial Group started out as a service company. One of our first moves was to hire people who already had a wealth of experience and knowledge of overhead cranes and their maintenance. The majority of our technicians have many years’ experience, and many of the managers on our teams are former seasoned technicians. For these reasons, our expertise in overhead crane maintenance is extensive.

In this article, we’ll answer the following questions :

- What is overhead crane maintenance?

- How often should an overhead crane be serviced?

- Are there any legal requirements or standards to be followed for maintenance?

- How much does overhead crane maintenance cost?

By the time you’ve finished reading, you will have a clearer idea of your responsibilities as a lifting equipment owner. You will know how to maintain it properly to comply with legal standards. This will help you avoid accidents and limit productivity losses. You will now know what to do to avoid the frustration of unpleasant surprises not only on your equipment, but also on your wallet.

Let’s start with the basics: what is overhead crane maintenance?

What is overhead crane maintenance?

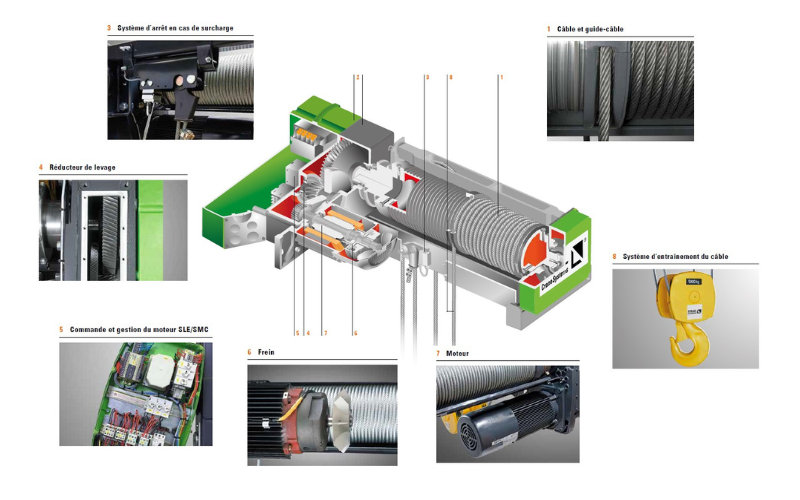

Overhead crane maintenance consists of a series of actions to ensure that the equipment remains in good condition. To achieve this, a competent person must first regularly check the many mechanical and electrical parts to ensure that they comply with standards. Then, when anomalies are detected, adjustments or repairs must be made. It’s the same principle as inspecting and repairing a car.

But how do you know when maintenance is due?

How often should an overhead crane be serviced?

Overhead crane maintenance begins with an inspection. How often does it need to be done? It’s the classification that determines the frequency of hoist inspections. For more details on this subject, see the article Crane and hoist classifications. Once the program has been drawn up, the inspections will help identify the interventions necessary to bring the overhead crane back into good working order. For example, the inspection report may indicate that certain repairs are urgent, while others simply need to be monitored. It’s the equipment owner’s responsibility to ensure that the technician’s recommendations are followed. Why is it so important to take action to correct problems identified during inspection?

Are there any legal requirements or standards for maintenance?

Yes, there are very strict standards for the maintenance of lifting equipment. The Canadian standard is CSA B167-16, which applies to overhead cranes, gantry cranes, monorails, hoists and jib cranes. This document also refers to the equipment manufacturer’s standards and to provincial laws and regulations. In Quebec, the Act respecting occupational health and safety requires owners of lifting equipment to maintain it in good condition (LSST, article 51). The Regulation respecting occupational health and safety (RROHS section XXIII) provides a more detailed framework for this type of machine.

The legal consequences of non-compliance can range from fines to prosecution, depending on the seriousness of the situation.

This means that maintaining lifting equipment not only ensures constant productivity and prevents accidents but is also necessary to meet obligations under current laws and standards. But is this maintenance expensive?

How much does it cost to maintain an overhead crane?

This is an important question, because the investment in a lifting solution involves not only the equipment itself, but also the maintenance costs over its lifetime. But is it really possible to determine how much it will cost? Yes.

To establish the cost of maintenance, the following elements must be evaluated: :

- The classe of use : to determine the frequency of inspections

- The hourly rate for labor and technician travel

- The distance of the technician from the equipment site

- The price of inspections (which may be a combination of the elements above)

- The price of the main spare parts for the equipment, and their service life

- The estimate time for repairs and service calls

You can use our article on crane and hoist classifications and our page on prices to estimate this cost if you wish.

Help with your maintenance program

Whether you’re planning to buy an overhead crane, or have a complete fleet of equipment, overhead crane maintenance should be a constant preoccupation for you. Why should it be? Because, unfortunately, these machines won’t maintain themselves… yet! We’ve seen that lifting equipment must be constantly maintained in good condition by a competent person, not only for productivity and safety, but also to comply with current standards. We’ve also seen that it’s possible to determine a budget, so that you know how much money to set aside to keep this equipment in good condition.

If you don’t have a well-established maintenance program, sooner or later productivity or safety problems will arise. And the resulting costs have been proved to be far greater than a well-planned maintenance program. You can then greatly reduce unpleasant surprises and frustrations. But where to start?

The first step is to determine the class of use of your equipment, which will determine the frequency of inspections. From there, you can draw up your program and calculate the exact cost of maintaining your equipment. You can also consult our team, who have extensive experience in overhead crane maintenance. Simply fill in the form at the bottom of the page, and we’ll be happy to help you with your project.

Représentant technique chez Groupe Industriel Premium inc.

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.