-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

Are there any standard overhead crane models?

7:27

Some industries sell standard products. Others only sell “custom made” products. What about overhead crane companies?

At Premium, we work on over 150 overhead crane projects a year. When analyzing our customers’ needs, many of them told me they wanted a standard overhead crane. For example, a similar industry has installed 2T or 3T equipment in its plant. Since your application is similar, you may feel that this equipment is a standard that will meet your needs. But what is the reality? Are there standard overhead crane models, or are all overhead cranes custom-made? These are important questions, because buying the wrong overhead crane based on standards could leave you deeply unsatisfied.

This article will teach you what is standard in the lifting field, but also how these elements are used to obtain the overhead crane that meets your needs. And most importantly, you’ll see how a customized approach ensures optimum performance for your unique application.

Let’s start by determining the right approach to evaluate the type of overhead crane that’s right for you.

What is the best way to determine which overhead crane I need ?

Every company has its own procedures and operations, and therefore its own requirements in terms of lifting height, equipment span and capacity, for example. It all depends on your operations, your application and the configuration of the building where the overhead crane will be installed. So, even if a particular type of overhead crane is more commonly found on the market, or used by another company in the same industry, it doesn’t mean it’s right for you.

Your specialist will start by analyzing your operations and your reality, then select standard components to design the overhead crane that will meet your needs. Which ones, for example?

What standard components are commonly used in overhead crane solutions ?

The following list details products that are frequently seen on the market or are basic models for creating your own lifting solution. But each component or configuration listed here comes with an explanation of what is meant by “standard” :

The type of overhead crane

The top-running overhead crane is used in around 90% of all overhead crane solutions installed, compared to an under-running overhead crane. It’s true that top-running cranes are less expensive. But the configuration of your building is what will often determine the type of overhead crane recommended (see the article Overhead crane project in a new building: avoid the pitfall with 5 checks).

The lifting height

Lifting heights between 20ft and 30ft are very common. But this measurement is also related to common building heights. Your equipment can be designed with the lifting height required for your application. Find out how you can maximize it in the article The 5 solutions to increase the lifting height.

The overhead crane span

Overhead cranes often have spans of between 30ft and 50ft, to accommodate common building configurations. Steel beams are generally used for these dimensions, while caissons will normally be used for spans of 60ft and over. However, your lifting specialist will design an overhead crane with a span exactly corresponding to the size you need. There are no prefabricated overhead cranes with pre-established dimensions that will fit your crane runway. Every overhead crane is different.

Hoists models and capacities

1T, 2T, 3T and 5T chain hoists are commonly used for small-capacity applications. The 5T, 10T, 15T and 20T wire rope hoists are used for heavier applications, depending on requirements (see article Are wire rope hoists preferable to chain hoists? What are the differences?) Unlike overhead cranes, every hoist is not custom designed. But these common models serve as basis for designing your custom lifting equipment, not as standards on which to build. Rather, they should be seen as capacity ranges.

Based on your operational requirements, your specialist will recommend the ideal hoist, taking into account your duty cycle, lifting speed needs, and the reel’s required lifting capacity.

The speeds

Lifting speeds of 6m/min (meter per minute) and travel speeds of 25-32m/min are “standard” operating speeds in line with the average heights (mentioned above) and frequent types of operation. For example, a horizontal travel too quick may cause the load to sway more than usual, presenting a safety risk. But many other speeds are available, and the choice will depend much more on the type of industry and application.

STANDARD OPERATING SPEEDS (most common speeds in blue) METER/MINUTE

Low

High

Hoist

Varies according to manufacturers' hoist ranges and operations

0.8

1

1,6

2

1

1,6

2

4.8

6

9,6

12

6

9,6

12

Cart

For spans of less than 30', we recommend 12.5m/min.

3.2

6.3

8

10

6.3

8

10

12.5

25

32

40

25

32

40

Overhead crane

Varies according to travel distance and track length. Variable speed drives are recommended for speeds over 50 m/min.

6.3

8

10

12.5

8

10

12.5

25

32

40

50

32

40

50

OTHER SPEEDS AVAILABLE ON REQUEST

The control

The wireless remote control (radio transmitter/receiver system) has practically become the standard compared to wired control. But this is a technological evolution combined with safety considerations. Radio transmitters offer many advantages, such as tandem lifting, for example (see article “What are the advantages of tandem lifting”). But wired control is still available.

The power supply

Usually, the industrial power supply in Canada is 575v or 480v, which is why the vast majority of industrial lifting equipment is connected to this type of power supply. A single-phase (120v) power supply is not recommended for industrial overhead crane. However, there are solutions if a 575v power supply is not available in your building (rotary phase for example. Consult your electrician).

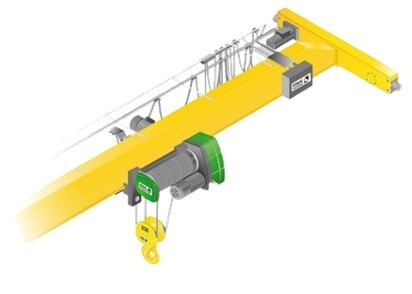

The color and your logo

That’s right! Many people think yellow is standard! But apart from the fact that this color represents safety, there’s no reason to stick with it if you prefer another color.

And why not customize it with your logo? In addition to the color, we can add your logo to the overhead crane. A simple solution to showcase your brand and assert your identity.

Now that we understand that some components are common, but all solutions are unique, let’s see how to turn your project into a success!

Now that we understand that some components are common, but all solutions are unique, let’s see how to turn your project into a success!

An overhead crane tailored to your needs requires analysis by an specialist

In this article, we demystified what’s standard and what’s not. We’ve learned that standard product models are used to create a unique solution that matches your operations. Now you know that the type of overhead crane, the lifting height, the capacity, the speeds and even the color of your lifting equipment can be customized, so you don’t have to buy equipment that disappoints you. But how can you be sure that your choice of overhead crane will be the best one, and that it will play its full part in ensuring your company’s productivity and profitability?

The analysis of a specialist is what will allow you to see all the possibilities. He or she will be able to help you design the lifting device you need! But where to start with your project? First of all, you might want to read the blog post "Need an overhead crane: Where to start?", which will help you gather all the information you need for your specialist. Then all you have to do is contact him or her, and they will help you configure the overhead crane that will become… your standard!

Contact our team by filing in the form at the bottom of this page to design your optimized lifting solution with one of our specialists.

Technical representative at Premium Industrial Group inc.

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.