-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

How thick should my concrete slab be to install an overhead crane structure?

October 25, 2024

How thick should my concrete slab be to install an overhead crane structure?

8:15

When assessing your operations, you’ve no doubt determined precisely where your overhead crane will travel and lift, and perhaps even imagined the position of the structure’s columns. This arrangement is certainly important to you! But now you’ve been informed that your plan will have to be modified because of a technical detail: your concrete slab isn’t thick enough for the planned installation! And yet, your floor has long been able to withstand the loads of other heavy machinery!

In fact, the thickness of your concrete slab is an essential element to check as soon as possible, as it can really thwart your plans for your future overhead crane.

Premium Industrial Group regularly addresses this type of problem on customer projects. Solutions exist to ensure load distribution and preserve the crane’s approach to guarantee the desired lifting operations.

In this article, we’ll take a look at how the load distribution of lifting equipment on a concrete slab works, what methods are used to anchor the structure, and above all, how a too-thin concrete slab impacts an overhead crane structure installation. We’ll then look at the measures that can be taken to compensate for this problem, to preserve your operations and avoid upsetting all your plans.

The overhead crane, a load in motion

First of all, there’s a key point to understand when it comes to installing an overhead crane and its structure in your environment: an overhead crane is not a static load. It’s a load in motion, moving up and down (lifting) and in different directions (translating).

These movements generate continuous tensile and compressive forces during use. If left unchecked, these forces would cause structures to shift or topple, with potentially catastrophic consequences for structural integrity, and a constant danger to workers.

This is where the fastening to your concrete slab comes in, to counter the effect of these forces on the installation.

Anchoring the structure and the thickness of the concrete slab

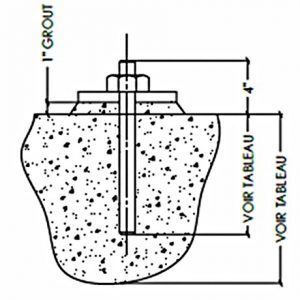

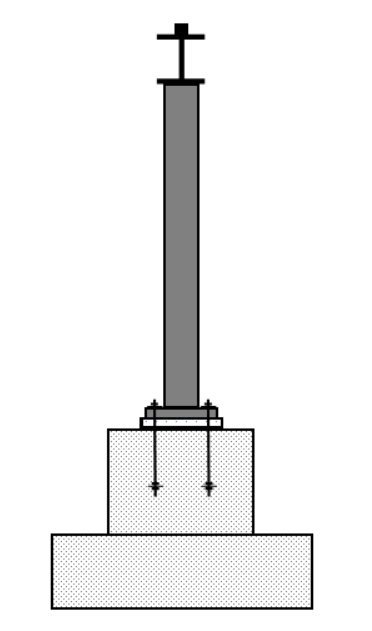

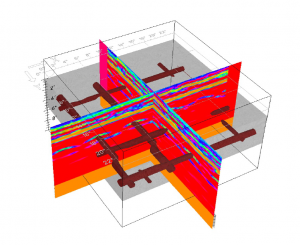

The preceding explanations help us to understand the important role played by the structure’s attachments to the concrete slab. The structure’s columns are supported on the ground by a plate and anchored in the concrete. This plate at the base of the column is what serves to distribute the forces transmitted by the overhead crane when lifting, moving or braking. It allows the loads of the column to be distributed evenly over a larger surface of the concrete slab, thus reducing the pressure on it.

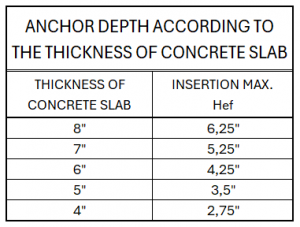

As for the anchors at the bottom of the columns, they play a role in the stability of the structure, preventing any lateral movement or tilting under the effect of the overhead crane forces. They are designed to resist tensile forces (pulling the column upwards) and compressive forces (pushing the column downwards). However, these anchors must be inserted at specific depths according to slab thickness to ensure stability (see table below).

The effects of a too-thin concrete slab

All these explanations are quite technical! But what are the impacts of a concrete slab whose thickness is different from what is commonly seen in industries (see box “6” concrete slabs in the industrial environment”)?

When a concrete slab is thicker than 6″, it’s usually good news for your overhead crane project. Why is this good news? Because the thicker the slab, the greater the load it can support.

6" concrete slabs in industrial environments

In general, the thickness of concrete slabs found in the vast majority of industries is 6”. This is why your crane supplier will undoubtedly take this thickness into account when assessing your project budget.

But sometimes an older building, or one with a different vocation in the past, may have a concrete slab of a different thickness. Which is why this element needs to be assessed by a specialist.

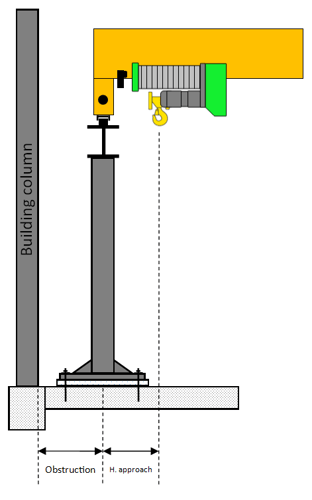

However, a concrete slab less than 6″ thick could crack under the weight of the equipment.. That’s why, when this is the case, installing a self-supporting structure will probably involve wider plates under the columns to further distribute the loads. The problem is that the wider the plate, the further the column has to be from the wall, reducing the approach of your crane’s hook.. In other words, this plate determines how far away from the wall the column can be positioned. And the closer it is to the wall, the more space there is to maneuver the lift (called the hook approach) and the fewer areas the equipment can’t go to (called the obstruction). And that’s where this change can run counter to your production’s original operating plan and force you to reconsider it!

Suddenly discovering that your concrete slab is less than 6”, even if only in certain places, can be a complication in your project that will impact accessibility for important maneuvers. Which is why we will now discuss solutions for this type of situation.

How can I compensate for a too-thin concrete slab?

As we have seen, the purpose of the plates installed under the columns is to help redistribute the loads caused by the overhead crane. But fortunately, in certain cases there are other ways of distributing this load.

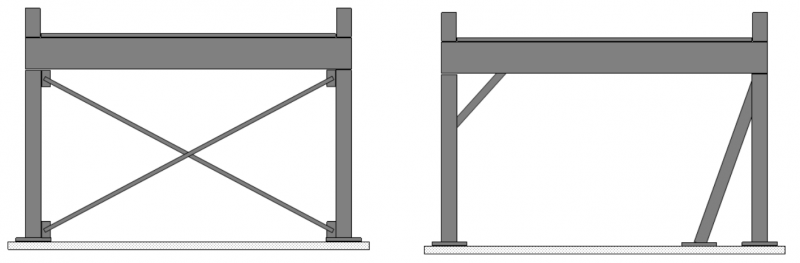

For example, when a slab varies between 4” and 6” and the lifting capacity of the overhead crane to be installed is less than 5000 kg, it is possible to add bracing to the design of the structure, which achieves the same objective. These consist of different types of bracing, positioned at different points, which again redistribute the load to reduce that taken from the floor. This may take the form of bracing between columns, or the addition of a column at an angle, often combined with an oversized plate beneath the column.

Example of bracing

On the other hand, in the case of a concrete slab of less than 4″, there is no choice but to rebuild the foundation under the columns. The foundation design will vary according to lifting capacity and soil type. At this stage, the company in charge of the work will have to carry it out under the construction decree, i.e. with an RBQ license and a qualified workforce (like our sister company Premium Industrial Structures, for example).

Example column with concrete foundation

However, in all cases one step is essential to analyze and calculate one of the solutions described above: engineering. An engineer specializing in overhead crane structures will have to evaluate the available options on a case-by-case basis. Obviously, there may be additional charges for this intervention. How does this involve the owner of the lifting equipment?

A crucial check… but you are not alone.

The thickness of the concrete slab required for the project should be indicated on the quotation provided to you by your lifting supplier and will also be specified on the technical drawings when reviewed for approval. Unless indicated otherwise, it is the responsibility of the building owner and purchaser to check that the concrete slab meets the required specifications. But how?

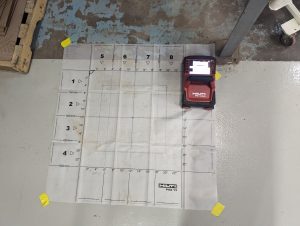

This information should be written on the building plans, and these should be accessible to the owner for consultation. It is also possible to check the concrete slab directly on site where the columns will be positioned.

Some companies offer a scanning or coring service to assess the actual thickness of your slab. Opting for this service avoids the inconvenience of an installation that does not comply with the supplier’s specifications. The structural solution can then be adapted before it goes into production. Another advantage of scanning is to ensure that the information on the plan has been respected, as the thickness of a concrete slab can occasionally differ from one place to another within the same building (e.g. 6“ of concrete in the center, but only 4” on the sides). Finally, this evaluation will also allow us to check whether the concrete is reinforced, i.e. whether it contains wire mesh or rebar.

” />

” /> Scanning service

Premium Industrial Group offers a scanning service and can assist should this kind of surprise arise 1 ! Contact us for more information on this service.

In conclusion, the thickness of a concrete slab is an element not to be neglected in your project to install an overhead crane structure. A slab that’s too thin has an impact not only on the design of the structure itself, but also on the operations you may have planned for your plant. This kind of detail needs to be analyzed as quickly as possible.

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.