Under running overhead cranes

No ground support for support columns? Are you looking for a solution integrated into the roof of your building for your lifting operations?

Suspended cranes, also known as under running cranes, are specially designed to meet these requirements.

What is an under running crane?

An under running overhead crane is a lifting device where the crane runs on rails attached directly to the ceiling (or to the building structure), unlike conventional overhead cranes which rest on rails laid on a structure.

Technical specifications

- Lifting capacity: up to ~ 16 metric tons

- Span: up to ~ 25 meters

- Lifting height: up to ~ 20 meters

- Hoist type: chain or wire rope

- Runway: H- or I-beam fixed to building ceiling

Possible configurations :

-

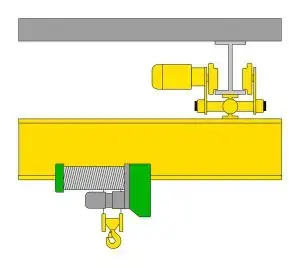

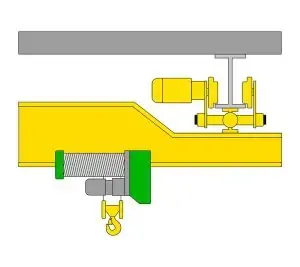

Single girder standard, double girder on request

-

Straight or flush-mounted connection

-

Other capacities, spans and lifting heights available on request