-

PRODUCTSreturn

-

SERVICES AND PARTS

-

ABOUT US

How can I create a safe maintenance zone for my overhead crane?

8:05

Author: Marc-André Martineau

Manager & Partner at Premium Industrial Group

Do you have several overhead cranes sharing the same crane runway?

Would you like to ensure the safety of your maintenance interventions while keeping your operations running?

In this article, we'll show you how to create a safe maintenance zone to avoid unnecessary downtime and the risk of electric shock.

Together, we'll talk about what a maintenance zone is, what it can do for your plant, and how to make it truly safe thanks to two essential elements: the buffer zone and the display.

What is an overhead crane maintenance area?

It's a portion of the crane runway that can be reserved for maintenance work when required. It is designed to prevent other cranes on the same track from entering this section. How does it work?

When the adjacent overhead crane approaches the zone, it ceases to be powered and stops itself. In this way, the technician can carry out maintenance on the lifting device in complete safety, while the other cranes continue to operate.

In general, this zone is located at the ends of the track, since this configuration is less costly. But it could be positioned anywhere along the track.

The length of the section can also vary according to your needs, for example, depending on the number of overhead cranes you wish to park there during maintenance. But its length will have to consider an essential element that we'll see later: the "buffer zone".

What are the advantages of the maintenance zone?

Normally, when maintenance is required on overhead cranes, the power supply has to be disconnected. However, when there are several overhead cranes on the same runway track, the power will be cut off to all the lifting devices. The maintenance zone makes it possible to cut power to only a portion of the track, by means of an electrical panel located between the power isolator and the conductor bars. Depending on your situation, this solution can offer the following benefits:

- Productivity: Maintenance of your critical overhead cranes can be carried out without stopping your operations

- Cost savings: Your maintenance zone can help you save money by avoiding the more expensive intervention of a technician outside normal working hours!

- Flexibility: Service technicians are naturally more available during working hours.

- Versatility: This solution could even be used to secure a section for work at height other than overhead crane maintenance. This could involve a variety of recurring tasks in an area crossed by the track.

- Safety: As we will see later, a true maintenance zone is safer from the risk of collision or electrocution.

Application example

This type of technology can be useful in many industries. But let's take the example of a steel distribution company with 5 overhead cranes on a 760 ft. track. It might decide to install 1 maintenance area at each end. Why would this be appropriate? In this type of industry, overhead cranes can be heavily used. They are often the main working tool for handling beams and for loading and unloading, with no other alternative.

So any industry where lifting equipment is central to productivity could benefit from evaluating the option of a maintenance zone.

Let's now take a closer look at the safety matter.

How does the maintenance zone enhance safety?

As mentioned above, the maintenance zone provides added safety so that a technician can carry out maintenance without risking electrocution or an adjacent lifting device colliding with the overhead crane. But for this system to be truly safe, it's necessary to include a "buffer zone". Why and how does it work?

A buffer zone for true zero energy

The first reason for a buffer zone is to ensure a true zero-energy maintenance zone. Why do we say this? To understand, let's first look at how overhead cranes are electrified.

Can true 0-energy be achieved simply with remote control management?Some people think that when the operator cuts off the power supply using the emergency stop function on the remote control, and that the remote control is carefully secured, it can be assumed that the intervention will be 0-energy. But in reality, this is not the case. For more information, see the box "What is a 0-energy overhead crane?" in the article "Working at height: Can an overhead crane be used to lift a worker or protect him from falling?" |

Electric current is transmitted to the overhead crane by conductor bars energized along their entire length. To ensure that this current reaches the equipment as it travels, it is collected by blades attached to the crane, which slide along the bar as it travels. These are known as collector shoes.

Electric current is transmitted to the overhead crane by conductor bars energized along their entire length. To ensure that this current reaches the equipment as it travels, it is collected by blades attached to the crane, which slide along the bar as it travels. These are known as collector shoes.

Theoretically, when these blades reach the padlocked section, they will be de-energized and the machine will stop. But in reality, and particularly when using a double shoe (two collector shoes following each other), the collector shoe system can itself transmit electrical current to the padlocked area! But how?

![]() If half the collector assembly has crossed the zero energy line, the other half is still in a powered section. As electricity is in constant movement, the area that should be current-free receives current from the part of the collector that is still energized (electrical conduction). The area supposed to be powerless is therefore energized at this precise moment. It's then necessary to wait until all the blades have moved to the 0-energy side before the current dissipates and no longer poses a danger.

If half the collector assembly has crossed the zero energy line, the other half is still in a powered section. As electricity is in constant movement, the area that should be current-free receives current from the part of the collector that is still energized (electrical conduction). The area supposed to be powerless is therefore energized at this precise moment. It's then necessary to wait until all the blades have moved to the 0-energy side before the current dissipates and no longer poses a danger.

Hence the importance of the buffer zone. This small section between the zero-energy zone and the energized zone serves as a transition to prevent electrical conduction. Without this crucial section, a technician working on an electrical component runs the risk of being electrocuted, even if he or she is in the maintenance zone.

A buffer zone for the complete stop of the overhead crane

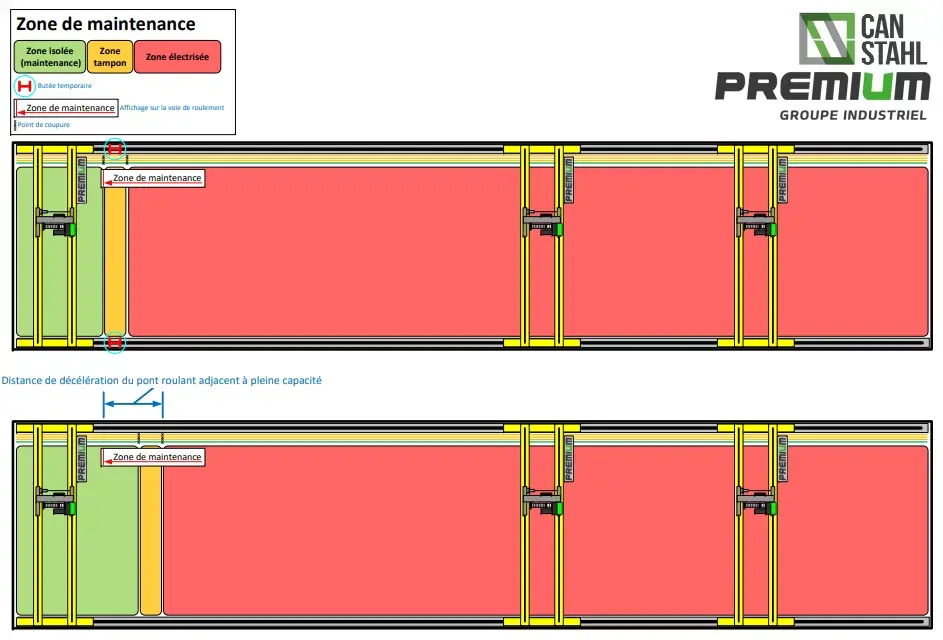

The second reason for a buffer zone is to give the crane enough time to come to a complete stop. Indeed, if an overhead crane crosses the maintenance zone, it will come to a halt, as it is no longer energized. But it has accumulated kinetic energy (force of movement) and won't come to a complete stop at once. It will slow down gradually before stopping completely. It is therefore important to consider the fully loaded deceleration of the adjacent lifting equipment when establishing the position of the buffer zone, otherwise a serious accident could occur (see the example in the image above).

In short, the buffer zone has two functions: to ensure true zero energy in the maintenance area, and to bring an approaching overhead crane to a complete stop. In other words, if no buffer zone has been provided, the maintenance area cannot be safe without the use of temporary end stops that will physically prevent any equipment from approaching it.

Clear display is essential

The second essential element of a safe maintenance area is display. It sounds simplistic, but the location of this safe zone must be clearly indicated to maintenance technicians. Clear display, such as signs on the runway track, should indicate where the maintenance zone begins and ends.

Talk to a specialist about feasibility at your plant

As you've seen, a safe maintenance zone guarantees true zero energy, reduces the risk of electric shock, and optimizes your maintenance interventions without interrupting your operations.

Would you like to know whether this type of installation is realistic in your industrial environment?

Our specialists can analyze your installations, design a zone tailored to your requirements, and assist you with its implementation.

You can contact one of our experts by clicking on the button at the bottom of this page. They will be able to help you assess the viability of your project and assist you in its realization.

Manager and partner at Premium Industrial Group

Learning Center

Whether you're an expert or know nothing about cranes, you'll find everything you need to know HERE.