24 Hour service

Emergency calls / Open 7 days

Today's technologies, used on modern lifting equipment, provide numerous possibilities to industries. This approach allows factories to produce in an efficient way, as some issues can be properly managed by this industrial intelligence. In the world of lifting, safety, flexibility and productivity are challenges that can be addressed with unsuspected technological solutions.

In this series of articles, we will discuss 4 common issues in handling heavy loads with overhead cranes. For every issue, we will look at the available solutions.

Growing companies have changing needs. As a result, load capacities can vary over time, but also over space. For example, certain production areas may have new requirements. Today's industry requires flexibility, without compromising the safety of personnel and equipment. Here are some examples:

In some work environments, it is sometimes necessary to use two hoists on the same crane (tandem) to lift the maximum load. But at other times, we may only need one of these hoists to lift the same load. Let's examine this case:

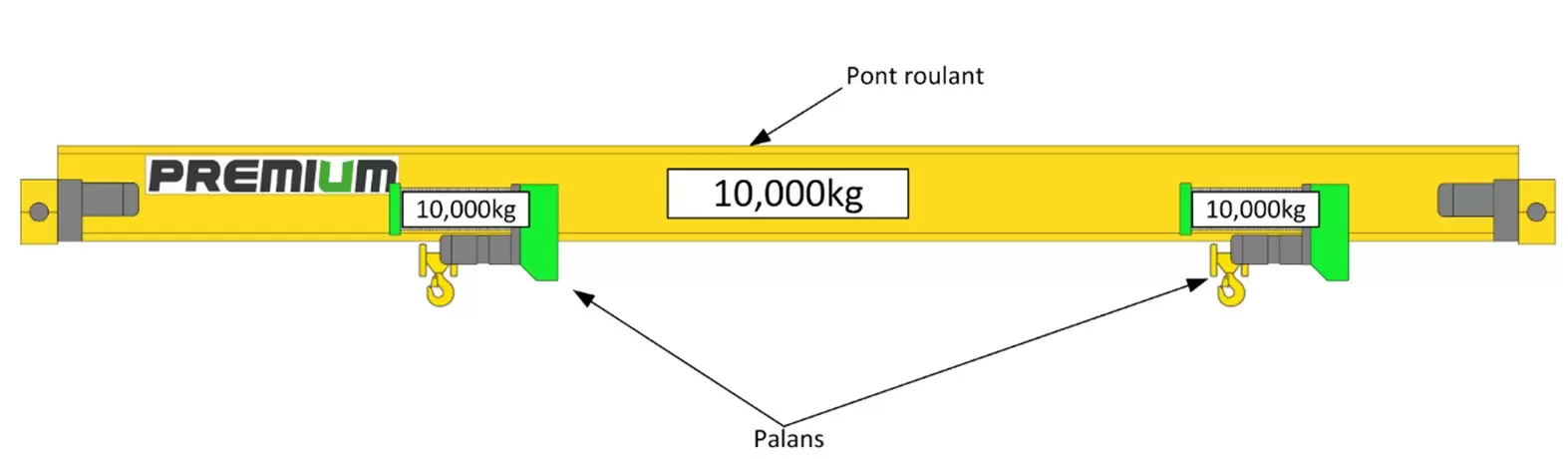

A 10,000 kg overhead crane, equipped with 2 hoists, is used to lift a component weighing approximately 10,000 kg. This part requires the use of both hoists. But in another area, another part, also weighing 10,000kg, must be lifted by only one hoist. If at least one of the 2 hoists can lift a load of 10,000 kg, this means that the sum of both hoists exceeds the rated capacity of the crane itself. What to do then?

It is possible to install a load summation module on tandem hoists. This technology allows the exchange of information between the 2 hoists to activate a load limiter based on the combined sum of the 2 loads. This device will prevent the crane's nominal capacity from being exceeded when using tandem hoists, while allowing the full load to be lifted when using a single hoist.

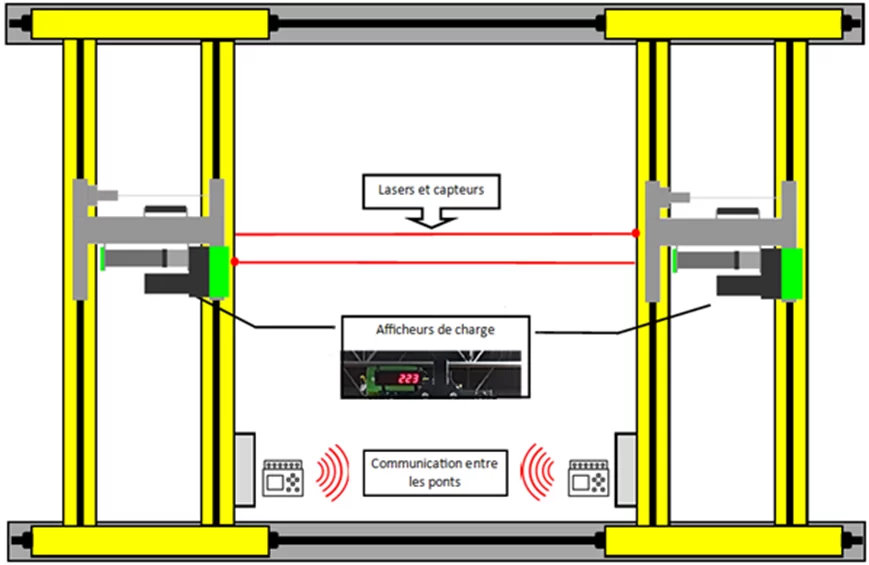

In some instances, it is the building structure itself that cannot support such a large load capacity in a small space. For example, a building might have been designed to accommodate two 20-ton bridges, but the structure cannot support the 40-ton load placed side by side. This design severely limits the available options. Or the building is expanded to accommodate a new 20-ton bridge on an existing track, but the older section of the building is only designed to take a 10-ton load.

For structural limitations, sensors can monitor positioning of the cranes in the facility and the actual combined weight of equipments operating in the same area. Through communication between the 2 cranes, this system will prevent the hoists from overloading sections of the building, but will also allow the 2 pieces of equipment to work in the same area when their combined capacity is safe. In addition, the crane will be restricted in its movement towards a sector where there is already a maximum load in use by another equipment.

These solutions provide great flexibility in operations while maximizing the available lifting areas. This means improved efficiency in the use of lifting space, and increased productivity as a result. In terms of safety, it helps avoid human error, thus protecting personnel and equipment.

In the lifting industry, technologies can be used to increase productivity, flexibility and safety. And that's just a glimpse of what can be done! Stay tuned for another solution to be discussed in the next article: the zoning system.

Learn more about the load management services offered by Groupe Industriel Premium.

Share this :You have a project in mind ?

Get a quote

To contact us, please fill out the contact form below. Some fields are required.

PREMIUM INDUSTRIAL GROUP

equips the following customers

Service Call

24 Hour service

Emergency calls / Open 7 days

Press 8 in the voicemail when the office is closed, A TECHNICIAN WILL COMMUMICATE WITH YOU WITHIN 15 MINUTES

Quebec Toll free :

1 888-650-0588

Montreal Toll free :

1 888-968-0588

Click on the button below to submit a request via form :